Peelply

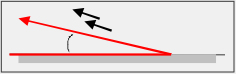

Peel the peel ply off in a point angle

Peel ply for defined surfaces in vacuum infusion and laminating processes

Peel ply in vacuum processes – Defined surface finish and process reliability

Peel ply, also referred to as release fabric, is an essential vacuum consumable in fiber-reinforced composite processing. It is used in vacuum infusion, vacuum compression, and wet lay-up to create a clean separation layer between the laminate and the auxiliary materials above. The fabric remains in place during curing and is removed afterward at a sharp angle, leaving behind a rough, adhesive-free surface. This surface can be directly bonded, coated, or painted without the need for sanding. Being permeable to air and resin, it supports both even resin distribution and effective laminate venting. The peel ply is made from nylon, available in various weaves, widths, and weights, and includes a colored tracer thread (red or blue) to facilitate easy identification and removal after the curing process.

Plain weave – Structured peel ply for controlled resin flow

Plain weave peel ply offers a stable and uniform texture, well-suited for CFK and GFK laminates with flat or slightly curved geometries. Its tight weave structure ensures controlled resin flow and prevents resin pooling. After curing, it can be removed cleanly without affecting the surface quality. The matte texture also enhances adhesion of subsequent layers. All plain weave options are made from nylon with a basis weight of 83 g/m². HP-Textiles offers a wide range of widths: HP-P83P3 (3 cm), HP-P83P4 (4 cm), HP-P83P5 (5 cm), HP-P83P8 (8 cm), HP-P83P10 (10 cm), HP-P83P15 (15 cm), and HP-P83P20 (20 cm). For larger applications, there are HP-P83P60 (60 cm) , HP-P83P100 (100 cm), and HP-P83P150 (150 cm). Versions such as HP-P83P60RB (60 cm) and HP-P83P100RB (100 cm) include a red tracer yarn for improved visibility. All products are supplied in 100 m rolls and are compatible with both epoxy and polyester resin systems.

Twill weave – Drapable peel ply for complex part geometries

For multi-dimensional or contoured laminates, twill weave peel ply is particularly advantageous. Its soft and flexible structure offers excellent drapeability, conforming easily to rounded or angular shapes. Despite its flexibility, it remains stable during vacuum bagging and can be removed evenly after curing – ideal for sensitive surfaces. HP-Textiles offers the HP-T105P with a basis weight of 105 g/m². It is available in several widths, including HP-T105P25 (25 cm), HP-T105P100 (100 cm), and HP-T105P125 (125 cm). This type is suitable for mold construction, carbon fiber layups, marine applications, and model making, where dimensional accuracy is critical.

Combined systems – Triplex mesh with integrated peel ply

For optimized processing, HP-Textiles offers Triplex Mesh – a pre-configured multi-layer material that combines peel ply, perforated release film, and breather mesh in one product. This three-in-one system saves time, reduces layup errors, and promotes a repeatable vacuum infusion process. Two variants are available: HP-TX275/152 (275 g/m², 152 cm width) and HP-TX280/150 (280 g/m², 150 cm width). Both are made of chemically resistant HDPE and available in colors such as blue, white, red, or yellow. They are suitable for epoxy and polyester resin systems and can be integrated into both manual and automated setups. These products are especially beneficial for large laminates, serial production, or time-sensitive applications.

Application areas for peel ply in composite manufacturing

Peel ply is a fundamental auxiliary material in nearly all vacuum-based CFK and GFK applications. Common use cases include structural composite manufacturing, mold making, aerospace, lightweight construction, marine and yacht building, prototype construction, and industrial laminates. It is used for surface preparation, as a release layer, and to structure the laminate stack. The choice between plain weave, twill weave, or a combined solution like Triplex Mesh depends on the part geometry, resin system, and the desired surface quality. When combined with perforated films, breather fabrics, vacuum films, sealant tapes, and flow media, it forms a coordinated vacuum consumable setup for reliable and consistent infusion results.

.jpg)

.jpg)

.jpg)